Marine awarded for designing the Corps’ first fully NDAA-compliant 3D-printed drone at $700 a pop

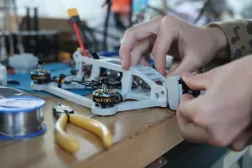

At roughly $700 per base model, the HANX platform is the Marine Corps’ first 3D-printed drone that complies with laws prohibiting the U.S. military from acquiring and using unmanned aerial systems with parts from certain foreign entities, according to the service.

Marine Sgt. Henry David Volpe, an automotive maintenance technician with the 2nd Marine Logistics Group out of Camp Lejeune in North Carolina, was credited as having led the development of the HANX drone, which can be modified for different military tasks and can carry a one-kilogram payload.

Taking his previous experience with 3D printing to the II Marine Expeditionary Force Innovation Campus — the unit’s hub for Marines to tinker with design modeling, robotics and manufacturing to come up with solutions for “ground level” problems — Volpe got to work on developing HANX, to include ensuring it complies with the National Defense Authorization Act, or NDAA.

“Anyone can create a cheap drone using cheap non-approved parts,” Volpe, for whom HANX is named after, said in a service press release last week. “However, finding parts that don’t run the risk of having backdoor software is difficult.”

A spokesperson for his unit told DefenseScoop Volpe is set to receive the Navy and Marine Corps Commendation Medal for his efforts.

For the U.S. military to use drones, the parts need to comply with the NDAA to avoid using material from adversarial countries such as China over supply chain and security concerns. Just last year, Marines were learning how to build small drones, but they were using cheap, readily-available Chinese components to do so.

The UAS supply chain has proved to be a significant hurdle amid a wide availability of low-cost components made around the world, especially China. Late last year, DefenseScoop reported that a majority of drones cleared through the military’s UAS vetting program had motors sourced from China, though officials said those components were considered low risk for exploitation.

“These systems are rigorously vetted to ensure they are NDAA-compliant and do not contain critical components from covered foreign entities,” Lt. Col. Eric Flanagan, a spokesperson for the Marine Corps, told DefenseScoop of the Corps’ “primary operational drone fleet,” which were approved programs of record and through the military’s Blue UAS cleared list.

He said the service is “fully committed to complying with” military policy, congressional mandates and the NDAA.

“While our training systems are strictly compliant, the Marine Corps does utilize a separate set of commercial off-the-shelf (COTS) drones for specific, non-networked purposes,” he said in part of a response to DefenseScoop’s question about NDAA compliance and if the service was using parts from China. He did not say where the COTS drones were from. “A key use for these systems is to realistically simulate adversary capabilities during training exercises.”

Those platforms, he added, are never connected to any military network and the “practice allows our Marines to train against the types of systems they might actually face, enhancing their readiness and counter-UAS skills.”

As the military top-shops establish more formal processes to develop and produce unmanned aerial systems, junior troops from multiple branches have been designing their own — and the services have been using them.

Volpe visited Fort Campbell, Kentucky, where soldiers have developed their own home-grown drones. In true interservice rivalry fashion, he was inspired to make his own.

“Their drone has some capabilities mine doesn’t, and some very nice cameras with it, but what I saw was a big price tag. I knew I could make something far cheaper without sacrificing too many features,” he said. “The [Army] design and hardware selection was also contracted out to third and fourth parties, making their 3D-printed drone an assembly [that] can’t be entirely done by soldiers.”

DefenseScoop reported in January that the Marine Corps was anticipating buying 10,000 first-person-view drones this year after it standardized a training program for its troops to certify on small UAS use. The service asked industry to make these drones for under $4,000 per unit, but with HANX ringing in at a fraction of that price, 3D-printed systems could play a big role.

A spokesperson for 2nd Marine Logistics Group, 1st Lt. Jorin Hollenbeak told DefenseScoop that the cost of HANX could change depending on what accessories are added to it, and its maximum range is still being tested.

“This in-house manufacturing capability is a key part of our broader strategy to equip all of our formations with an appropriate mix of unmanned systems,” Flanagan said. “While it is premature to provide exact figures on how many 3D-printed drones will be part of our overall inventory, this capability allows us to be more agile, cost-effective, and responsive to the evolving threats on the battlefield.”

Hollenbeak said multiple units within II MEF have shown interest in modifying HANX for specific uses, including explosive ordnance disposal and public affairs. The Innovation Campus is exploring ways to use the system for offensive, logistics and surveillance training, he noted.

“I had never accomplished something like this,” Volpe said, according to the press release. “I’ve been to college before, rebuilt engines, but this is mine. This is what I designed. This is what I made.”