Ursa Major tackles US solid rocket motor shortage with 3D printing

With the United States experiencing a constrained supply chain of solid rocket motors, Colorado-based Ursa Major plans to design and manufacture the key components with 3D printing technology.

On Monday, the rocket and engine manufacturer announced the technique — dubbed Lynx — as a solution for America’s solid rocket motor (SRM) industry, which is “plagued by a broken supply chain and an overextended industrial base,” according to a company press release.

Ursa Major’s additive manufacturing technology aims to restore depleted solid rocket motor inventories at a faster and more cost-effective pace, Joe Laurienti, the company’s CEO, said in a statement.

“We’ve adapted our extensive experience in additive manufacturing, materials development, and propulsion production to the most pressing problems facing the SRM industry,” Laurienti said. “The result is an adaptable manufacturing process that is designed to mass produce multiple systems, rapidly switching from one model to another, producing reliable SRMs quickly and at scale, while leaving room to collaborate across the industry on energetics.”

The status of the United States’ inventory of weapons, munitions and components has come under scrutiny as the Pentagon continues to send military assistance to Ukraine, particularly items that rely on solid rocket motors.

Many of the weapons transfers to Ukraine — including Javelin anti-tank weapons, Guided Multiple Launch Rocket System (GMLRS) rockets and Stinger missiles — have depleted U.S. stockpiles. A study published in January by the Center for Strategic and International Studies found that with “recent” production rates, it would take around eight years to replenish Javelin inventories and 18 years to replace Stingers.

“Traditional SRM providers rely on production lines that are difficult to re-tool, expensive to ramp up, and dependent on a significant workforce to operate,” an Ursa Major press release said.

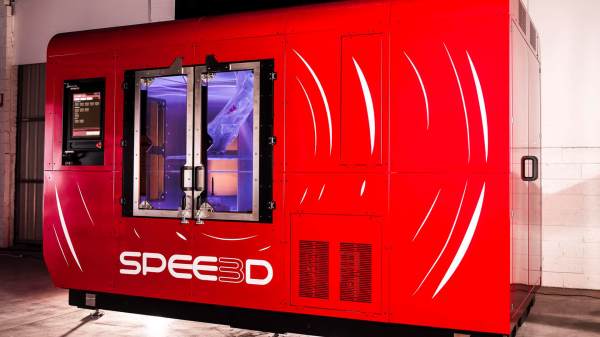

The company hopes to flip that standard on its head with Lynx, which leverages flexible and scalable additive manufacturing techniques to restore SRM inventories. The 3D printer enables faster manufacturing rates at lower costs using fewer parts, and can easily pivot production from one solid rocket motor to a different system due to its “one-click” changeover, according to Ursa Major.

Lynx SRMs are designed to carry more propellant with the same engine size, meaning they could offer more capability than current motor systems, the company noted. The design also allows for a single propellant to be used for different motors.

“This approach could address supply chain challenges often associated with developing bespoke propellants for each individual motor application and could enable increased collaboration with other industry partners,” a company press release stated.

While Ursa Major did not disclose whether it was already contracted to produce solid rocket motors, nor specifically which ones, the company noted it plans to scale the approach to different sized motors and applications during the next year — citing recent consolidations and shakeups in the rocket motor industry that might prompt defense contractors to seek alternative means of production.

Northrop Grumman and Aerojet Rocketdyne — which was acquired by L3Harris in July — have long been the two sole suppliers of solid rocket motors in the United States. However, the recent demand for SRMs has prompted companies like Ursa Major, as well as X-Bow Systems and Anduril, to bolster supply chain capacity.